View Our Range

Stillages, CAGES, TROLLEYS & RACKS MADE IN THE UK.

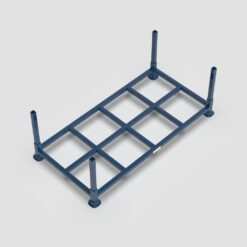

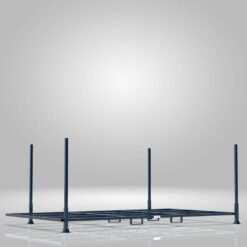

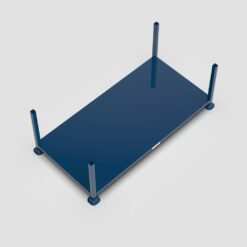

We’re a family run business that specialises in manufacturing high-quality stillages, cages, trolleys and other material handling products. All products are manufactured in the UK, ensuring the highest levels of quality and craftsmanship. With fast delivery and free quotes from specialist engineers, we offer unparalleled service to our customers. If you can’t find the product you need on our website, we can manufacture it for you to meet your specific requirements. Trust in Lowe Stillages and Cages for all your material handling needs.

Providing material & handling SOLUTIONS for the biggest and best in the business

Lowe stillages & cages in action: Transforming Industries

Products in the video manufactured by Lowe

Some of our great clients…

What sets us apart from Competitors?

Firstly, over many years we have worked closely with our clients in providing solutions to their complex material handling storage/trolley etc. requirements. Problem solving is our strength, whatever the issue we can provide a solution.

Lowe deliver a complete solution to your material handling requirements. From your initial concept, we produce a detailed 3D design, working with you all the way through the design process, until reaching an agreed drawing.

Our purpose-built production facility is based in the heart of Staffordshire. We custom build every fabrication, taking the steel from its rawest state straight through to a high-quality product. Our fabrications are built by skilled engineers to last. During every stage of the production process our products are inspected to ensure the highest standards.

We pride ourselves not only on just providing the perfect product/ solution, but the relationship that we have with our customers for the foreseeable future. If you have any issues or problems that need solving further down the line, we will always be here to assist.

The Lowe CE MArked Stillage & Cage Range

Why Choose Lowe?

At Lowe UK we offer unrivalled customer service to ensure you get the best possible solution to whatever the project may be. We have over 25 years of experience working across many different sectors, from automotive and heavy industry to events and construction. Our team of dedicated highly skilled engineers have backgrounds in process development/management, continuous improvement and supply chain and logistics and take pride in offering the very best solution every time. Our aim is always to ensure that we offer a robust solution, that is commercially viable quickly and efficiently working with you from inception until delivery.

Once you have raised an inquiry one of our technical project engineers with be in contact to go through all of the details big and small to grasp the scope of the project going forward. If the project requires our engineers will be happy to come to the site, to ensure no stone is left unturned.

As soon as our engineers have enough information about the project they will start to design and develop a concept, taking all factors into account and ensuring that they meet all of your requirements. As this process progresses you will have regular contact and updates keeping you informed of changes and timescales. When the concept is complete you will be offered an online design review with the engineer where you can go through all the details of the concept to tweak and change the design until all parties are happy.

Upon acceptance of the concept a prototype will be manufactured, again you will be in close contact with the engineer to keep you updated of progress and lead times. When the prototype is fully manufactured, we will invite you to our manufacturing facility in Staffordshire for a site acceptance test. This process is to highlight any potential issues prior to delivery to ensure the implementation process runs as smoothly as possible.

When the prototype has been delivered the engineer will once again visit your site for the factory acceptance test to trial the solution in real-life conditions. This test could highlight issues such as ground conditions, process inefficiencies, or just general tweaks to perfect the product for the intended use. If any issues are found during the factory test Lowe UK will carry out the required changes and repeat the process until all parties are satisfied with the outcome.